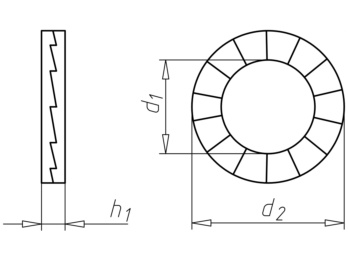

Serrated lock washer pair Wide model

Steel, Delta Protekt (DPE)

DIN 25201 M12X25,4 DT

Art.-no. 0401770012

EAN 4053479758343

With registration you can access the Würth Elektro online shop selection.

General information:

Lock washer as per DIN 25201, prevents screw connections from loosening when faced with lateral stress, shocks, or vibration.

Corrosion resistance:

600 hours of base metal corrosion as per DIN EN ISO 9227-NSS (DIN 50021-SS) – cf.: 96 hours, yellow zinc plated (A2C)

Operation:

Two serrated lock washers combine in a wedge fashion, ensuring an extremely durable hold. The screw connection is held fast by pre-tension instead of friction.

Benefits:

- Easy assembly and disassembly (serrated lock washers come pre-glued into pairs)

- Tested system for screw locking (locking elements prevent screw from opening) at high and low pre-tension

- Particularly well suited for dynamic load – even with lubricants

- Reusable with consistent quality

- Does not harm surfaces

- Also usable with strong hardness class 8.8, 10.9, and 12.9 screws and corresponding nuts

- Available in stainless and regular steel (other materials available on request)

- Available with narrow and wide contact area

In screw-to-nut connections the serrated lock washer pair must be used below both the screw head and the nut. Torque recommendations are laid out in DIN/ISO list specifications.

Datasheets(X)

| |

Internal diameter (d) | 13.0 mm |

Suitable for screw thread | M12 |

Outer diameter (d) | 25.4 mm |

Thickness (h) | 3.7 mm |

Material | Steel |

Vickers hardness, HV | 485 HV |

Surface | Flake zinc silver |

Corrosion protection period | 600 h |

RoHS-compliant | Yes |

Design | Wide |

Locking function | Locking against self-loosening by mechanical interlocking |

Notice | In screw-to-nut connections the serrated lock washer pair must be used below both the screw head and the nut. Torque recommendations are laid out in DIN/ISO list specifications. |